-

Phone

86-371-5****

-

Address

No. 68, Jingnansi Road, Economic and Developing Zone, Zhengzhou, Henan, China

-

E-mail

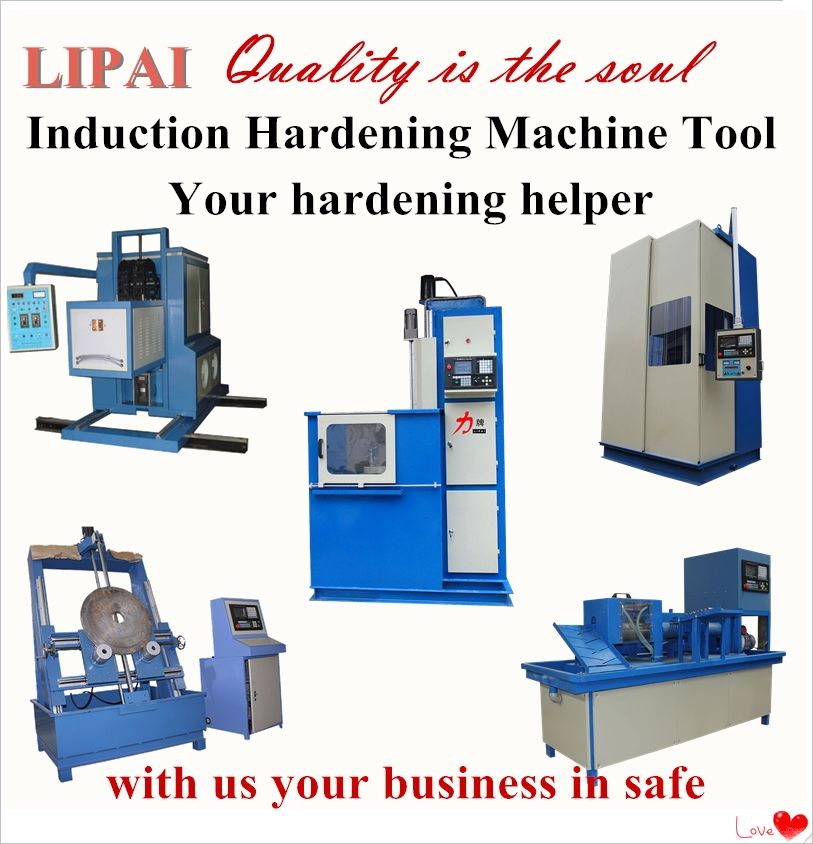

Zhengzhou Induction Multi-Function Hardening Machine Tool

Machine Tool, Machine Tool for Quenching, Hradening Machine Tool

Description

- Model NO.: LP-SK

- Process Usage: Metal-Cutting CNC Machine Tools

- Control Method: Closed-Loop Control

- Processing Precision: 0.01~0.02(mm)

- Certification: GS, SGS, CE, RoHS, ISO 9001

- Accessories: Coils, Foot Pedal, Operating Instructions

- Service: The Whole Life

- Engineer: Enginner Overseas Avaiable

- Energy: Electirc

- Principle: Series Resonance Circuit

- Trademark: LIPAI

- Specification: CE/ISO/SGS

- HS Code: 8514400090

- Application: Metal

- Movement Method: Contour Control

- Numerical Control: CNC/MNC

- Performance Classification: Economical CNC Machine Tools

- Condition: New

- Warranty: 12 Months

- Install: Install Video, Sketch Are Available

- Manufacture: Zhengzhou Gou′s

- Electric Consumption: Save 10%-30% Electric Than Other Heating Method

- Circuit: IGBT Series Resonace Circuit

- Transport Package: Standard Wooden Case

- Origin: Zhengzhou, Henan, China

Induction Heating Hardening Machine Tool

Part 1: What is heating, hardening machine tool?

To speak briefly, it is a good hardening helper.

It has become more and more popular in hardening process.

It helps your work-piece arrive the best hardening result,

by automatic moving the workp-piece and controling the moving speed.

Such as moving the shaft or gear with reasonable speed, to make gear or shaft to be the best.

According to the difference of work-piece, vertical and horizontal type are available for your choice.

Part 2: Application of hardening machine tool

Heat Treatment like annealing, normalizing, quenching, forging, tempering.

1. Hardware and tools, such as plier, wrench, hammer, ax, screwing tools and shear (orchard shear).

2. Automobile and motorcycle fittings, such as crankshaft, connecting rod, piston pin, chain wheel, aluminum wheel, valve, rock arm shaft, semi drive shaft, small shaft and fork.3. Electric tools, suchas gear and axes.

4. Machine tools, such as lathe deck and guide rail.

5. Various hardware metal parts and machined parts, such as big shaft, gear (chain wheel), camshaft, chuck and clamp etc.

6. Hardware molds, such as small-size mold, mold accessory and inner hole of mold.

Part 3: Main characteristics:

1. Adoping MOSFGT and IGBT inverting device, tracking frequency automatically

2. High frequency, heated quickly, its powei consumption is only 20%~30% of eletronic tube induction heating machine and other heating style.

3. Security and reliability, the equipments have the secure voltage and it's secure to operate

4. Manual, automatic regulating automatically, it can protect itself from over voltage, over current, lack of water, phase fail, over hot, etc

5. It has no open-fire, noise and pollution, be suit for the environmental protection and fire, improve the image of the company

6. Recommend usage: Welding, forging, melting, quenching, annealing, etc.

Technical Parameter: take LP-SK-2500 as a example.

| Model | LP-SK-2500 |

| Max Gear Diameter | 2500mm |

| Max Workpiece Weight | 1.5t |

| Transformer Moving Distance( up and down) | 450mm |

| Transformer Moving Speed( up and down) | 1-80mm/s |

| Transformer Radial Moving Distance | 650mm |

| Transformer Flotation Distance | X,Y±20 |

| Transformer Horizontal Adjustment Distance | ±25mm |

| Control Type | PLC |

Part 4: What can we do for you?

1. Choosing a suitable machine for you.

2. meet your special needs to provide machines work best.

3. To be your best partner, solve all your problem about induction heating.

(with us your money in safe your business in safe)

4. After-sale Service:

One year warranty; spare parts replacement is free within one year

Long-term technical service;

Overseas on-site technician service is satisfied

engineer will be dispatched to your factory to install machine and train your works.

Payment terms: 30% deposit, 70% before shipping

Production time: 10-25 working days

Shipping by sea, air, DHL

Part 5: Who we are?

1. Name: Zhengzhou Gao's Electromagnetic Induction Heating Equipment Co., Ltd

2. Detail: A manufacturer and trading company of induction heating machine with 20 years.

Products sell well in Domestic market, Mid East, Southeast Asia, South Asia, Eastern Asia, America, Europe, Africa, Oceania etc.

Hope this 20 years old manufacturer can enjoy a lucky chance to provide you competitive price and high quality products.

Our aim is to reduce your cost, improve your efficiency. Help you to start business better, get more money and achievement.

Contact Thea for details

: +86 152 2519 9097

Time is gold. Inquiry will be replied within 12 hours.

To be our VIP customer, 3% discount!